IOSI supports research at all technology readiness levels, including proof-of-concept, with a clear line-of-sight towards technology commercialization in oil sands mining operations, in the four research themes: Bitumen Extraction, Instrumentation, Oil Sands Mining, and Mine Closure. The current focus areas are described below.

Extraction

Bitumen Extraction

Focus 2025/2026: Aqueous and hybrid extraction

Background

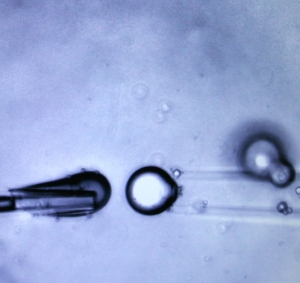

Mined oil sands industry uses a water-based extraction process to separate bitumen from oil sands ore. Here, the mined oil sands – after being crushed – are mixed with hot process water and caustic to form a slurry. The slurry is transferred to separation vessels via hydrotransport lines where ore lumps are mechanically sheared, and bitumen gets aerated. The aerated bitumen is separated in the form of froth in the primary separation cell. The unrecovered bitumen is subjected to air flotation. Kearl Oil Sands uses Paraffin Froth Treatment (PFT) process to separate bitumen from water and solids. Over 90% of bitumen recovery can be achieved in the water-based process depending on the ore grade and the processing conditions.

For more information on the extraction process, including at Imperial Oil, please refer to:

-

- Bitumen extraction by Oil Sands Magazine: https://www.oilsandsmagazine.com/technical/mining/extraction and links therein

- Kearl Mine (Imperial Oil) by Oil Sands Magazine: https://www.oilsandsmagazine.com/projects/imperial-oil-kearl-mine and links therein

- Mining for bitumen by Oil Sands Magazine: https://www.oilsandsmagazine.com/technical/mining/

Technology and Knowledge Gaps

- Alternative chemicals for poor processing ores.

- Methods for decreasing extraction GHG emission.

- Reducing water usage for the extraction process.

- Methods/processes that can further enhance bitumen separation.

- Fundamental understanding of bitumen aeration and de-aeration process and methods to improve both.

- Development of new technologies for de-aeration of bitumen froth.

- Fundamental understanding of hybrid extraction process (solvent/water) to reduce process temperature.

- Using computational methods to develop predictive models (transient and steady-state) for different stages of oil sands processing.

- Fundamental science for producing cleaner froth (i.e., fewer solids) in extraction including hydrodynamics of underwash and overwash systems.

- Methods to reduce fines generated by extraction.

- Relationship between slurry conditioning and bitumen recovery and novel rapid conditioning approaches.

- Development of technologies and processes to enable mobile aqueous extraction units for remote mining locations vs. central extraction processing plant: enhanced separation; short residence time; fewer smaller-scale equipment units; production of dry tailings.

Preferred Processes and Methods

- Alternative chemicals.

- New process concepts or enhancement of the current practice that could be integrated into the existing process at the central facility or enable remote mining locations.

- Low GHG emission, non-solvent approaches.

- Processing to minimize waste rejection.

Instrumentation

2025/2026 Focus: Measurements for extraction plant optimization

Background

Mined oil sands industry uses a water-based extraction process to separate bitumen from oil sands ore. Here, the mined oil sands – after being crushed – are mixed with hot process water and caustic to form a slurry. The slurry is transferred to separation vessels via hydrotransport lines where ore lumps are mechanically sheared, and bitumen gets aerated. The aerated bitumen is separated in the form of froth in the primary separation cell. The unrecovered bitumen is subjected to air flotation. Kearl Oil Sands uses Paraffin Froth Treatment (PFT) process to separate bitumen from water and solids. Over 90% of bitumen recovery can be achieved in the water-based process depending on the ore grade and the processing conditions.

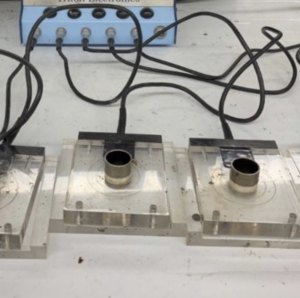

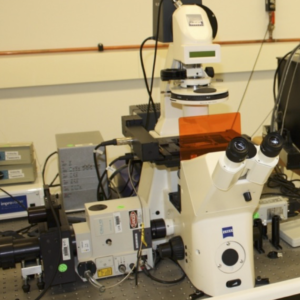

The extraction plant operation relies on the accurate measurements of components of interest in the process streams. Online instrumentation, as well as fast ex-situ measurements, minimize response time, which translates into a stable plant performance with improved bitumen yield, reduced GHG emissions, water consumption and volume of rejected tailings.

For more information on the extraction process, including at Imperial Oil, please refer to the links provided below:

- Bitumen extraction by Oil Sands Magazine: https://www.oilsandsmagazine.com/technical/mining/extraction and links therein (paraffinic froth treatment)

- Kearl Mine (Imperial Oil) by Oil Sands Magazine: https://www.oilsandsmagazine.com/projects/imperial-oil-kearl-mine and links therein

- Mining for bitumen by Oil Sands Magazine: https://www.oilsandsmagazine.com/technical/mining/

Technology and Knowledge Gaps

- Measurement tool for the size distribution of solids / lumps downstream of the crushing plant and lump measurements in hydrotransport close to the primary separation cell (PSC) inlet to understand ablation. Detect frozen lumps in hydrotransport.

- Real time tailings flocculation performance instrumentation for inline flocculation and thickeners.

- Real-time or near-real-time tool for mine face ore characterization for ore sorting.

- Identify alternative sensing technologies and lab data-based models to meet the needs of industrial online measurements.

Preferred Processes and Methods

- Online measurement techniques and equipment that could be integrated into the existing process.

- When considering a new online measurement technique, sensor surface fouling or abrasion plugging of slip streams due to a combination of bitumen and sand must be kept in mind.

- Excluded from the Call are: AI- and machine-learning approaches based on the commercial data; use of NMR for crushed ore, cores slurries characterization; use of NIR for crushed ore characterization; use of hyperspectral analyzer for crushed ore or cores characterization; use of microwave sensing for metal or lump detection.

Instrumentation

Oil Sands Mining

2025 Focus: Materials and designs to improve reliability and efficiency in oil sands mining

Background

Due to the handling of abrasive oil sands materials, equipment used in the oil sands mining industry experiences a much shorter service life than other mining industries. Equipment covers from front mining moving equipment 7495 shovels or equivalent models, 797F haul trucks, dozers, graders, to plant, ore preparation plant crushers, conveyer, apron feeder chain, vibrating screen, slurry pipeline and pumps etc. The damage mechanisms depend on service conditions: dry abrasion (high, low stress or combined), impact, erosion, corrosion or erosion-corrosion or fatigue cracking.

For more information on the mining process and related material challenges, including at Imperial Oil, refer to the links provided below:

- Kearl Mine (Imperial Oil) by Oil Sands Magazine: https://www.oilsandsmagazine.com/projects/imperial-oil-kearl-mine and links therein

- Materials and reliability in oil sands (MARIOS): https://innotechalberta.ca/services/materials-and-reliability-in-oil-sands-program/

Technology and Knowledge Gaps

- Current attachment methods of wear materials to base support metals suffer spalling off or cracking due to cyclic loading in operation. Very good wear-resistant materials cannot survive high-impact or high-stress abrasion conditions.

- 3D printing of hybrid materials or large components or repair is still not fully developed in the industry.

- Large equipment welding and designs suffer from cyclic loading fatigue service, how to improve its fatigue life is not fully optimized in industry, and the equipment experiences premature failures.

Preferred Processes and Methods

- New materials/technology to provide much-improved wear/fatigue performance compared to current weld overlay, casted wear materials, OEM tires, ropes, etc.

- Improved attachment method/designs for wear-resistant materials to base supporting metals.

- Repairing technology on polymer/cast iron materials to provide comparable wear resistance as base material.

- Advanced inspection technology, like robotics, NDT methods to inspect parts/areas that are hard to reach or cannot be inspected with current NDT methods.

- New engineering design/materials/methods to improve fatigue life on mine mobile equipment.

- New technology that can reduce parts lead time, inventory, improve designs and operating efficiency.

Mine Closure

2025/2026 Focus: Geotechnical engineering, reclamation, and tailings-derived materials for closure.

Background

Oil sands operations in Alberta produce large volumes of tailings which are a mixture of water, sand, clay, and residual bitumen. The composition of these tailings varies depending on the process stream. These tailings are stored in external tailing dams or in-pit mined areas that must be eventually reclaimed and decommissioned in the long term.

Effective mine closure strategies are essential for ensuring the long-term stability of tailings structures and the reclamation of surrounding environments. For terrestrial closure approaches, success largely depends on maximizing water removal from tailings and minimizing the volume requiring long-term management—both of which accelerate reclamation timelines. However, oil sands tailings, particularly fine-dominated deposits (where over 50% weight [wt%] of particles are smaller than 44 μm), pose significant challenges due to their slow consolidation rates. These conditions can delay the initiation of closure and capping activities, resulting in prolonged monitoring and regulatory commitments for operators.

Current treatment technologies, such as thickeners and enhanced in-line flocculation (eILF), are widely used to improve dewatering efficiency. Thickeners promote dewatering by allowing solids to settle under gravity, while eILF enhances particle aggregation using chemical flocculants, improving fines capture and reducing water content. Despite these advancements, the industry still faces challenges in finding an economical methodology to achieve dewatered tailings with high solids content (greater than 60 wt%) which is essential for meeting reclamation, capping and closure objectives. Moreover, the long-term consolidation behaviour and geotechnical stability of treated tailings deposits are still not fully understood. Addressing these knowledge gaps is vital for developing sustainable and effective mine closure strategies.

At the same time, oil sands tailings offer an opportunity as feedstocks for value-added processing that generate useful materials for applications at mining sites. To be viable, these processes must clearly demonstrate both economic and environmental benefits.

Technology and Knowledge Gaps

- Develop operationally practical solutions for capping of soft tailings deposits (such as residual pond-bottom fluid fine tailings (FFT), thickened tailings (TT), froth treatment tailings (FTT, tailing solvent recovery unit [TSRU]) which are being affected by lack of reliable predictions of settlement and understanding of the strengths (related to capping).

- Explore feasibility of outlet design to convey water from the tailings’ facilities post closure (how to manage surface water out of tailings structure at closure and post closure).

- Explore low GHG emissions, low energy intensity, low-waste technologies with minimal processing or simple additives to transform tailings into materials that can be used on mining sites, such as substrates to improve water and land reclamation, capping and mine closure, etc.

- Explore the use of novel materials, including those derived from tailings, to enhance the closure process (geochemical and geotechnical stability).

- Design and implement reclamation strategies that promote development of target ecosystems and landforms to productive states (i.e., possible target land uses, such as forestry, traditional land use, etc.). This work also includes improving technical confidence in achieving a given target ecosystem, considering the variability in surface settlement and water tables, as well as methods for accommodating settlement overtime.

- Develop novel tools including remote sensing for determining progressive reclamation trajectory for large scale areas.

- Sulphide mineral oxidation mitigations for Coarse Sand Tailings in pre or post depositions.

- Explore the mitigations methods to enhance geochemical stability of Froth Treatment Tailings (FTT/ TSRU).

Preferred Processes and Methods

- Solutions should support long-term environmental sustainability and reduce adverse impacts on surrounding ecosystems during and after mine closure. Approaches should be economically viable, avoiding excessive treatment and resource use and materials should be available in the region (cost-effective).

- Encourage the development of novel materials and methods that can be applied to future mine closure projects (novel and innovation methods).

- When TSRU tailings is the feedstock, the preferable form is wet TSRU tailings, before or after separation by gravity (solids in TSRU tailings settle by gravity and form a dense 60 wt.% sediment).

- Excluded from the Call are: active water treatment; methods to separate water from TSRU tailings; methods to convert bitumen/asphaltenes/maltenes into value-added products; methods which use solvents or high temperatures.

Mine Closure